The road ahead: How we’ll get to 54.5 mpg by 2025

Obama wants to double the avg. fuel efficiency next decade—tough, but doable.

At the end of August this year, the US Department of Transport's National Highway Traffic Safety Administration (NHTSA) and the US Environmental Protection Agency (EPA) announced new standards to significantly improve the fuel economy of cars and light trucks by 2025. Last week,

we took a look at a range of recent engine technologies that car companies have been deploying in aid of better fuel efficiency today. But what about the cars of tomorrow, or next week? What do Detroit, or Stuttgart, or Tokyo have waiting in the wings that will get to the Obama administration's target of 54.5 miles per gallon (mpg) by 2025?

The problem is historic

Whatever the technology, it's going to involve gasoline for at least the foreseeable future in the US. Automotive history helps us understand why. Author and journalist LJK Setright told us "we need hardly worry about who invented the motor car." While there are several inventors to whom the first horseless carriages can be attributed, Setright had a point when drawing the starting line through 1885 and Karl Benz's gas-powered three-wheeled machine. Victorian and Edwardian car makers drew on a wide range of fuels and engines. If a man in the street then predicted the next century, it wouldn't have been unreasonable to expect a diverse vehicular landscape. Back then, electric cars were

marketed to women as they neither gave off clouds of exhaust nor required someone strong to crank the engine over (the invention of the electric starter motor finished this feature off). By 1900, Thomas Edison was ready to pick this technology as the winner. Electricity might be

making a comeback now, but it was the internal combustion engine—powered either by gas or diesel—that made automobile what it is. Unlike steam, drivers didn't need to stop for heavy fuel to burn or to top up the water for their boilers. Back then, much like today, batteries didn't charge fast enough or contain enough energy to meet most of our needs. But liquid hydrocarbons are cheap and easy to extract, they have good energy density, and don't require high pressure containment. So for over a century, the infrastructure to support the gas-powered car built up across the globe.

Of course, burning hydrocarbons isn't problem-free. They are a finite resource, one we're pulling out of the ground much faster than it took to get down there in the first place. Many of the richest deposits are controlled by autocratic or otherwise unpleasant regimes, upon which another nation might not wish to depend. And then there's the waste problem: nitrogen compounds can cause respiratory disease; lead additives affect development; and the big one, carbon dioxide, drives climate change. Despite these issues, the depth of infrastructure to support the gasoline engine is such that, for the foreseeable future, alternatives like hydrogen or even electricity will remain very niche choices.

The MPG equation

The basics of today's engines may have been put together more than 130 years ago, but that hasn't stopped engineers and scientists from finding new ways to travel further on the same gallon. That benefits drivers who have to pay to fill up their tank, as well as to society at large. It's why governments are using differing approaches to increase fuel efficiency. In Europe, that's mainly via escalating gas taxes, but here in the US we have the Corporate Average Fuel Efficiency (CAFE) regulations.

Enlarge

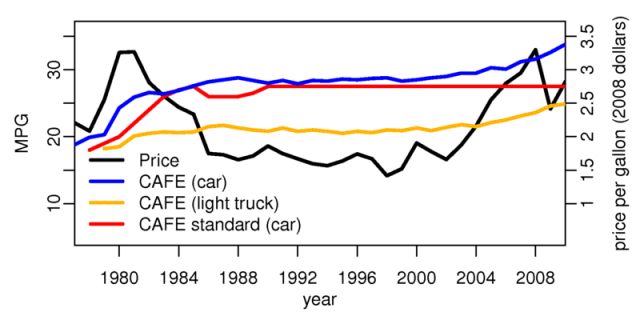

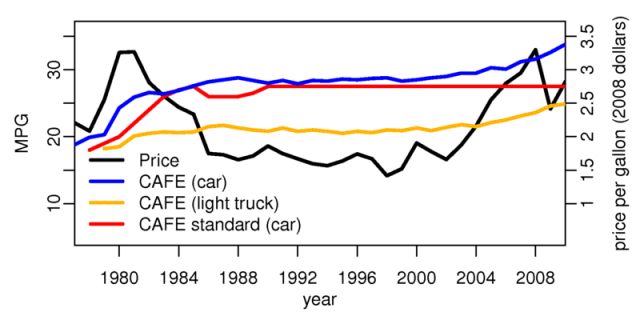

Enlarge / Evolving CAFE standards. Price inflation adjusted to 2008 dollars.

Wikimedia Commons

CAFE was introduced following the oil crisis in 1979 resulting from the Iranian revolution. It started with a modest goal, a mere 18 mpg, something even the Ford Model T was capable of achieving. CAFE increased average fuel efficiency over a number of years, up to 27 mpg in the mid-1980s, but the 1990s saw both oil prices and the idea of the US government exercising regulatory power both drop like stones. There we languished, until rising oil prices and growing sentiment about the need to address climate change intervened (such are the difficulties of making anything happen in Washington, DC). It was actually the car companies that moved first this time around, sensing that parsimonious punters might respond well. DC followed, and in August 2012, the government published new CAFE regulations that will raise average fuel economy to 54.5 mpg by 2025—almost double what they were a mere two years ago (you can find an interesting infographic showing the last 100 years of fuel economy

here.)

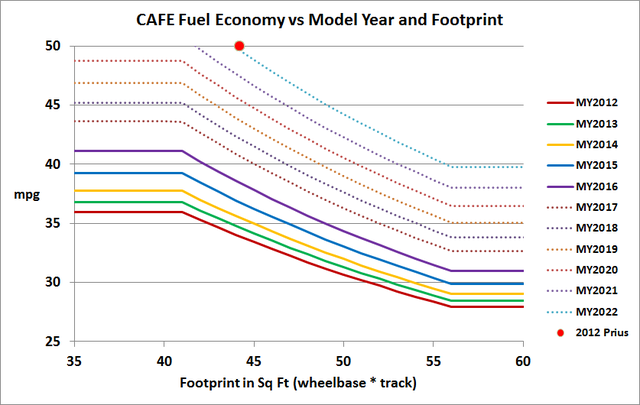

Now, it's important to note that what CAFE says is a 54.5 mpg car and what the EPA says is a 54.5 mpg car are not really the same thing. For one thing, CAFE standards apply to, and are calculated for, a company's entire product lineup based on a complicated formula. That isn't the same as the simulation of supposedly real-world driving conditions that the EPA uses. What's more, within that product lineup, cars with a smaller footprint (say, a Mini) are expected to get better mileage than larger vehicles (your trucks or SUVs). So, in 2025, a car with a footprint of 41 sq. ft or less will be expected to deliver 61 mpg under CAFE, but only 43 mpg according to the EPA. At the other end of the scale, a truck with a footprint greater than 75 sq. ft only needs a CAFE rating of 30 mpg, or a mere 23 mpg from the EPA. Suddenly it seems like we're not even asking that much!

EPA/NHTSA Fuel Economy standards plus proposals through 2022, based on their published mathematical formulas.

James Adcock via Wikimedia Commons

At this point, some of you might be thinking "there are plenty of fuel-efficient cars, but they're all small and on sale in Europe!" Euro car nerds are but a tiny minority within these great United States. Most car buyers, whether they're in Manhattan, New York, or McAllen, Texas, are not going to be lining up for VW Lupos or Renault Twingos—even if they can do 70 mpg. But that's a problem of taste—let's worry about the technology first!

How the magic may happen

The first technology to consider is start-stop. It's arguably a current technology, at least in Europe where I've been hard pressed to rent a car without it. In fact, you could even get a VW Golf equipped with an early system as far back as 1994, but they didn't sell well. Since this is a US-centric site and start-stop is only just beginning to arrive on US roads, it counts.

Start-stop is designed to save gas when it's being most wasted, which is when the engine is running but the car is stationary (i.e. in a traffic jam). Simply, when the car comes to a halt, the engine cuts out. When it's time to move another car length forward, the engine refires and the driver carries on their merry way. One reason for the prevalence of start-stop in European cars, and its late arrival on these shores, is the preference our continental cousins have for manual transmissions. That's because stopping the engine when the car is stationary is the easier part.

Enlarge

Enlarge

© BMW.

As we discussed in part one, car engines are made up of many components with inertia and momentum. This means they can be started quickly, but not instantaneously. It's not so much of a problem with a manual transmission, as selecting first gear from neutral refires the engine (in practice—I've found it's still horribly easy to stall when trying to get moving quickly). But companies like Ford found it wasn't quite that simple with automatic transmissions.

In order to keep the gearbox's hydraulic pressure up, Ford fitted an electric pump. Also, to minimize the delay between the driver wanting to dart into an opening in traffic and the car moving, the transmission is kept in gear instead of dropping to neutral at a stop. "We had to develop some unique control algorithms for the engine and transmission to overcome this obstacle and still ensure an extremely quick, smooth, and quiet restart," said Birgit Sorgenfrei, Ford’s Auto Start-Stop program manager.

And to prevent the nightmare scenario of cars stranded in traffic jams with dead batteries, the control software also monitors the electrical drain on the car (from AC, audio, headlights, etc.) and disables start-stop when necessary. While start-stop doesn't offer much in the way of benefit when it comes to the EPA's fuel efficiency calculations, in city driving, such a system should be able to realize a gas saving of up to 10 percent. Not too shabby, but still not 54.4 in the near-term. Where do engines go from here?

The automotive industry has come up with plenty of ways to increase the efficiency of existing engines. Unfortunately, to reduce fuel consumption and emissions to the low levels of future standards, we can’t just rely on incremental improvements—entirely new kinds of internal combustion engines need to be developed. Fortunately, the research and industrial community has known this for the past few decades. They've been hard at work coming up with these.

Before talking about the new engine concepts, first we’ll dig a little deeper into how traditional engine types work to understand their limitations.

Gasoline? Diesel? What's the difference?

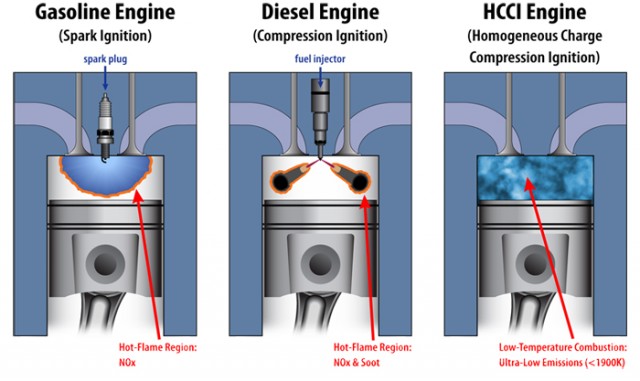

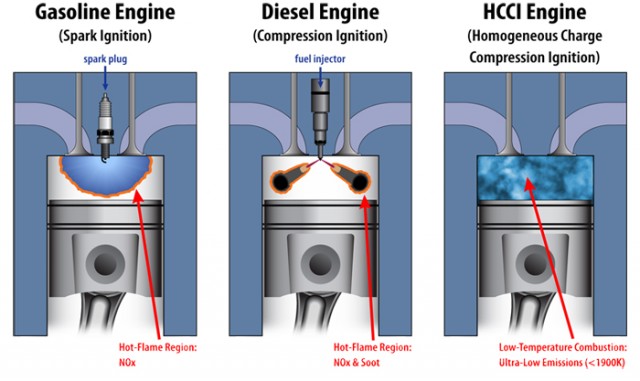

Gasoline and diesel engines differ mainly in how the mixture of fuel and air are ignited: gasoline engines rely on a spark, while diesel engines ignite only using compression to raise the temperature and pressure. (Hence the terms “spark ignition” and “compression ignition” used to describe the engine types). Both use four-stroke engine cycles—the difference is in the combustion.

Without getting into the nitty-gritty of the engine cycles and some complex thermodynamics equations, in an ideal world a gasoline engine (the Otto cycle) would actually be more efficient than a diesel (the Diesel cycle) all other things being equal—mainly, the compression ratio. Unfortunately for drivers of gasoline-powered cars everywhere, the tendency of gasoline to spontaneously ignite, or knock, at higher pressures and temperatures limits the compression ratio.

Diesel engines, on the other hand, are designed to ignite following compression, and can operate at much higher compression ratios (between 14:1 and 20:1, compared to around 10:1 for gasoline engines). This, combined with the slightly higher energy density by volume of diesel fuel, allows modern diesel engines to burn between 20 and 40 percent less fuel per mile—and therefore emit less carbon dioxide.

Gasoline and diesel engines also differ in the way they blend fuel and air together. In traditional gasoline engines, the fuel is mixed with air before compression through an intake port injection system—they are “premixed.” In most engines, this reactive cocktail contains just about enough fuel and air to burn completely, without any of either remaining: a stoichiometric mixture. The engine could inject less fuel into the mixture to make it “lean,” but the three-way catalytic converter used to treat the exhaust works best with a near-stoichiometric mixture. Burning a well-mixed, stoichiometric mixture also ensures complete combustion, generating a minimal amount of unburned hydrocarbons and carbon monoxide.

In contrast, diesel engines directly inject fuel into the cylinder when the air is fully compressed, where the high temperature quickly causes the mixture to ignite. In this case, the burning starts before the fuel and air mix completely, causing soot to form when the fuel can’t find enough air. Unlike a gasoline engine, diesel engines operate on lean fuel-air mixtures—adding more fuel would lead to more soot and unburned fuel coming out the exhaust. Too much fuel, or not enough air, is what causes a cloud of black smoke to erupt out of a diesel truck’s exhaust (typically when it’s driving past your open window).

This direct injection of fuel means the power of a diesel engine is controlled directly by the fuel supply. When you put the pedal to the metal, the injector increases the amount of fuel in the spray to 11. Gasoline engines, on the other hand, control power through the air supply via a throttle; sensors work with the injector to keep the fuel/air ratio relatively constant. The throttle—usually in the form of a butterfly valve—and fuel pump reduce the efficiency of gasoline engines, particularly when idling and cruising.

Enlarge

Enlarge / A VW TDI engine.

© Volkswagen

Both diesel and gasoline engines produce nitrogen oxides (NO[SUB]x[/SUB]), which contribute to air pollution and acid rain. High temperatures inside the engine cause the oxygen and nitrogen molecules in air to break apart, then recombine together in the forms of NO and NO[SUB]2[/SUB]. In both engines, the high temperatures leading to NO[SUB]X[/SUB] production are mostly caused by burning of near-stoichiometric mixtures: gasoline engines only operate at this ratio, and in diesel engines there are regions where the fuel and air can mix and burn completely.

Gasoline engines do have one advantage: easier cleanup of exhaust using a three-way catalytic converter. These simultaneously reduce emissions of NO[SUB]X[/SUB], carbon monoxide, and unburnt hydrocarbons through conversions into oxygen, carbon dioxide, and water. For optimal reduction of all three pollutants, the fuel/air mixture must be stoichiometric—too much or too little fuel would reduce the performance. Current catalytic converters rely on expensive precious metals like platinum and palladium, which increases the costs of gasoline engines.

There are also catalytic converters for diesel engines, but these are more complex than the single device used in gasoline engines. A diesel oxidation catalyst converts carbon monoxide and unburned hydrocarbons to water and carbon dioxide, but can’t eliminate the NO[SUB]X[/SUB]. Instead, in the newest diesel engines, a second converter is used that relies on selective catalytic reduction. This reacts NO[SUB]X[/SUB] with a reducing agent such as ammonia or urea to convert it into water and nitrogen.

Volkswagen put this system into their new EA 288 diesel engines, powering the next generation of diesel Golf, Jetta, and Passat models. The company

reported a 45 percent reduction in emissions over a more simple NO[SUB]X[/SUB] trap. The main downside is the requirement to store (and refill) liquid urea on the vehicle, in addition to the greater complexity and expense of the system.

So, there are advantages and disadvantages to both engine types. Diesel engines are more efficient, but require much more complex (and expensive) emissions controls. How can we improve upon these engine designs, in order to simultaneously improve fuel economy and reduce emissions? Well, two heads are better than one, right? The most potential lies in combining aspects of each into new engine types.

Direct injection in spark ignition engines

One idea is to adopt the direct fuel injection of diesel in a gasoline engine: spark ignition direct injection (SIDI) engine. Also called gasoline direct injection, this was actually first developed in 1925 and used throughout World War II in aircraft engines. Direct injection was employed in some automotive gasoline engines starting in the 1950s, but was mostly abandoned in the late 1970s in favor of stoichiometric-mixture port fuel injection. That method could benefit from significantly reduced emissions—able to meet then-new EPA regulations—thanks to the three-way catalytic converter.

But direct injection has a number of benefits over port fuel injection: it eliminates inefficiencies due to throttling and pumping, and the mixture is cooler, allowing a higher compression ratio—and lower octane gasoline—while still avoiding knock. In addition, direct injections cold-start easier, requiring less fuel and emitting less unburned hydrocarbons. All told, direct injection gasoline engines can use a quarter less fuel than the traditional port fuel injection engine.

However, it should be noted that direct injection has the same NO[SUB]X[/SUB] and soot emissions problems as diesel engines, and can’t use the three-way catalytic converter efficiently for the same reasons.

But in an effort to improve fuel economy, car manufacturers started to turn back to direct injection in the mid–1990s and have continued in this direction. In particular, performance cars adopted direct injection, likely due to the higher power offered by an increased compression ratio: the

Ferrari 458 and

Porsche 911,

Cayman S, and

Boxster S to name a few.

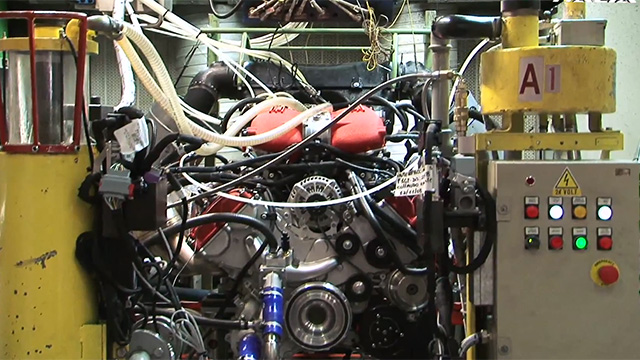

The engine for a Ferrari 458 Italia on the test bench at the factory.

Ferrari

For more modest applications, Ford developed the

EcoBoost family of engines, which rely on direct injection and turbocharging to reduce the size of the engine while offering the power of a larger one, increasing efficiency and reducing emissions. These engines

recirculate exhaust gas through the cylinder, lowering the temperature and therefore NO[SUB]X[/SUB] emissions. Ford is also

investigating (PDF) the combination of a three-way catalyst with either a NO[SUB]X[/SUB] trap or selective catalytic reduction system to meet even lower emissions standards.

Homogeneous charge compression ignition

What about combining the properties of the engines in another way? Take the premixed fuel and air of gasoline engines, and the compression ignition of diesels, and you have a homogeneous charge compression ignition, or HCCI, engine. “Homogeneous charge” refers to the blend of fuel and air that is well-mixed during compression (like a gasoline engine), compared with the fuel jet that is injected in a diesel engine.

Enlarge

Enlarge

Lawrence Livermore National Laboratory.

Assuming the mixture is well-mixed by turbulence, ignition actually occurs in multiple locations in the cylinder, causing rapid burning and fuel consumption. In gasoline engines, ignition occurs near the spark, while in diesel the edges of the injected fuel jet mix and burn with air. HCCI engines burn an extremely lean fuel-air mixture at a diesel-like compression ratio. Since the fuel and air are well-mixed before compression, the mixture burns cleaner and completely—meaning low carbon monoxide and unburned hydrocarbons.

The lean mixture also burns cooler (up to 500 degrees Celsius below gasoline or diesel engines), so the combustion generates small amounts of NO[SUB]X[/SUB]. The lower temperature also reduces heat transfer losses, increasing efficiency. To top it all off, soot doesn’t form during the burning of the lean, homogeneous mixture.

In other words, HCCI engines offer the low soot and NO[SUB]X[/SUB] emissions of gasoline engines—without requiring the catalytic exhaust aftertreatment—combined with the high efficiency of diesel engines: around 20 percent higher than gasoline. Sounds great, right? Where are our HCCI engine-powered cars?

Unfortunately, the same phenomena that give HCCI engine their benefits also introduce challenges. While physical processes control gasoline and diesel engines (spark and fuel injection), HCCI engines are controlled primarily by chemistry. And chemistry is more difficult to control, at least in the chaotic environment of an engine cylinder. A slight change in the wall temperature, or composition of remaining exhaust gases, and the ignition behaves differently.

Enlarge

Enlarge / A GM single-cylinder HCCI research engine with a computer-controlled valve actuation system.

© General Motors.

This situation is exacerbated by the fact that we don’t completely understand the behavior of gasoline and diesel under HCCI conditions. Academic, industrial, and national lab researchers are working tirelessly to fix this.

Another big problem with HCCI engines is the emission of carbon monoxide and unburned hydrocarbons, which can be greater than in gasoline or diesel engines. Since the fuel is blended with the air prior to compression, the crevice around the piston head traps fuel where it can’t be burned with the rest of the mixture. In a gasoline engine, some of this fuel would be released and consumed during the expansion stroke, but the low temperatures of HCCI engines prevent this. Low temperatures also prevent the complete conversion of carbon monoxide to carbon dioxide, especially at lower loads.

These challenges notwithstanding, car manufacturers have built working HCCI engines—even road-worthy prototypes.

GM developed a gasoline

hybrid HCCI/spark ignition engine that operates in HCCI mode from idle to 60 miles per hour and at cruise, otherwise switching to spark ignition operation. This is necessary, because at higher speeds, the temperature in the cylinder increases, causing the mixture to ignite early and knock. In tests performed using a Saturn Aura, with a modified 2.2-liter EcoTec four-cylinder engine, the hybrid achieved an average fuel economy of 15 percent better than a conventional spark ignition engine. Operation during the HCCI mode produced 90 percent less NO[SUB]X[/SUB] emissions compared to spark ignition.

As of 2009, GM hoped to have the first production engines in 2014. Since then, there has been little news about their progress. The most significant was a

research paper published last year discussing methods to extend HCCI operation to higher loads, which could eliminate the need for the spark ignition mode altogether.

Many other automotive companies, including

Volkswagen, Daimler, Ford, Honda, and

Bosch, also worked on developing HCCI engines. But no commercially available HCCI-powered vehicle exists today.

Any other acronyms out there?

The biggest problem with HCCI engines is the lack of control over ignition, particularly at higher temperatures. A few research groups came up with second-generation alternatives attempting to solve this problem. These concepts are much less mature than HCCI, although working engine prototypes have been built.

One approach, developed by a

group at the University of Wisconsin-Madison, controls the reactivity of the fuel-air mixture by injecting a blend of diesel and gasoline:

reactivity controlled compression ignition (RCCI). Compared to diesel, gasoline is less reactive—otherwise it would constantly spontaneously ignite and knock before the spark. By adding diesel, the reactivity of the fuel can be increased as necessary.

Professor Rolf Reitz, the leader of the research group, described the highly reactive diesel droplets in the fuel blend as “a collection of liquid spark plugs” that help ignite the gasoline.

At heavy loads, the fuel blend would contain little-to-no diesel, since the high temperatures in the engine cylinder easily ignite gasoline. When the engine is running at lighter loads, the temperature is lower, so a higher diesel content (up to around a 50–50 blend) would increase the reactivity of the blend as needed.

Since only the fuel is modified, RCCI engines would enjoy the same reduced emissions as HCCI engines.

In tests using a modified Caterpillar heavy-duty diesel engine, the group saw a thermal efficiency of up to 53 percent. That's higher than the most efficient diesel engine out there—a

giant two-stroke turbocharged engine used to drive container ships (which achieves 50 percent efficiency). For comparison, most traditional gasoline engines only reach a thermal efficiency of around 25 percent.

The main deficiency of this approach is the requirement to carry two fuels around, and the complex sensors and equipment needed to regulate the blend of gasoline and diesel.

In addition, the emissions of carbon monoxide and unburned hydrocarbons remain high, like HCCI engines. In an attempt to address this, recently the group

explored direct injection of both fuels, rather than the conventional port fuel injection. They found that this approach reduced hydrocarbon and carbon monoxide emissions, while keeping the same low NO[SUB]X[/SUB] and high performance of the original.

Argonne National Laboratory is working on another HCCI alternative, which they call

multizone stratified compression ignition (MSCI), that only requires low-octane gasoline paired with a modified diesel engine. The gasoline—at an octane number between 80 and 85—is a bit easier to ignite than the standard 87 gasoline at your pump, but still not as reactive as diesel. The MSCI engine uses a high compression ratio, heating the mixture up so that the gasoline spontaneously ignites. To keep the temperatures low like HCCI (for the reduced NO[SUB]X[/SUB]), exhaust gas is recycled in the cylinder.

The main innovation is in the fuel injection: unlike a diesel engine, which injects near the end of compression, here the gasoline is injected two or three times during the compression. This allows time to build layers of well-mixed fuel and air before ignition. Again, compare this to the standard direct injection approach, which dumps all the fuel in one spray, preventing it from mixing with air before burning.

Since the fuel and air are given time to mix, burning the blend produces near-zero soot and up to 80 percent less NO[SUB]X[/SUB] than conventional diesel engines.

How is this any better? Unlike HCCI, which relies completely on the chemistry of the mixture, MSCI engines can control the ignition by varying the timing, number, pressure, and other properties of the fuel sprays. Engine knock is avoided because the fuel is injected directly into the cylinder, so there isn’t time for the gasoline to react with air before the compression ends—where it is supposed to ignite.

This approach offers more control over ignition than the HCCI concept and doesn’t require two fuels like RCCI, but there is a downside: peak power reduced by about a quarter, caused by the exhaust gas recirculation. However, unless you are an underground street racer, or really like beating everyone out of an intersection when the light changes, this shouldn’t be a huge problem, as cruising power is unaffected.

Which of these directions will automobile engines follow? Unfortunately, it isn’t clear. It is likely that hybrid HCCI/spark ignition engines will hit the market in a few years, but a 15 to 20 percent improvement in fuel economy—while beneficial, to be sure—isn’t quite the revolution many evangelists had hoped for. The technology we need may very well be in its infancy right now, but 54.5 is still a bit away. Luckily, 2025 is too.

Join us next week for the final installment in the future of cars series, when we consider some of the other ways manufacturers are helping drivers eke out more miles on a tank of gas. Stay tuned for lightweight materials to autonomous cars that talk to traffic signals and each other for the most efficient journey.