You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Toronto Crosstown LRT: Mount Dennis Station and EMSF | ?m | 3s | Metrolinx | IBI Group

- Thread starter UT Admin

- Start date

SaugeenJunction

Senior Member

ProjectEnd

Superstar

ProjectEnd

Superstar

W. K. Lis

Superstar

At least the roofs have plant life.

W. K. Lis

Superstar

Kodak in Toronto, 1899-2005: A Century of Traces

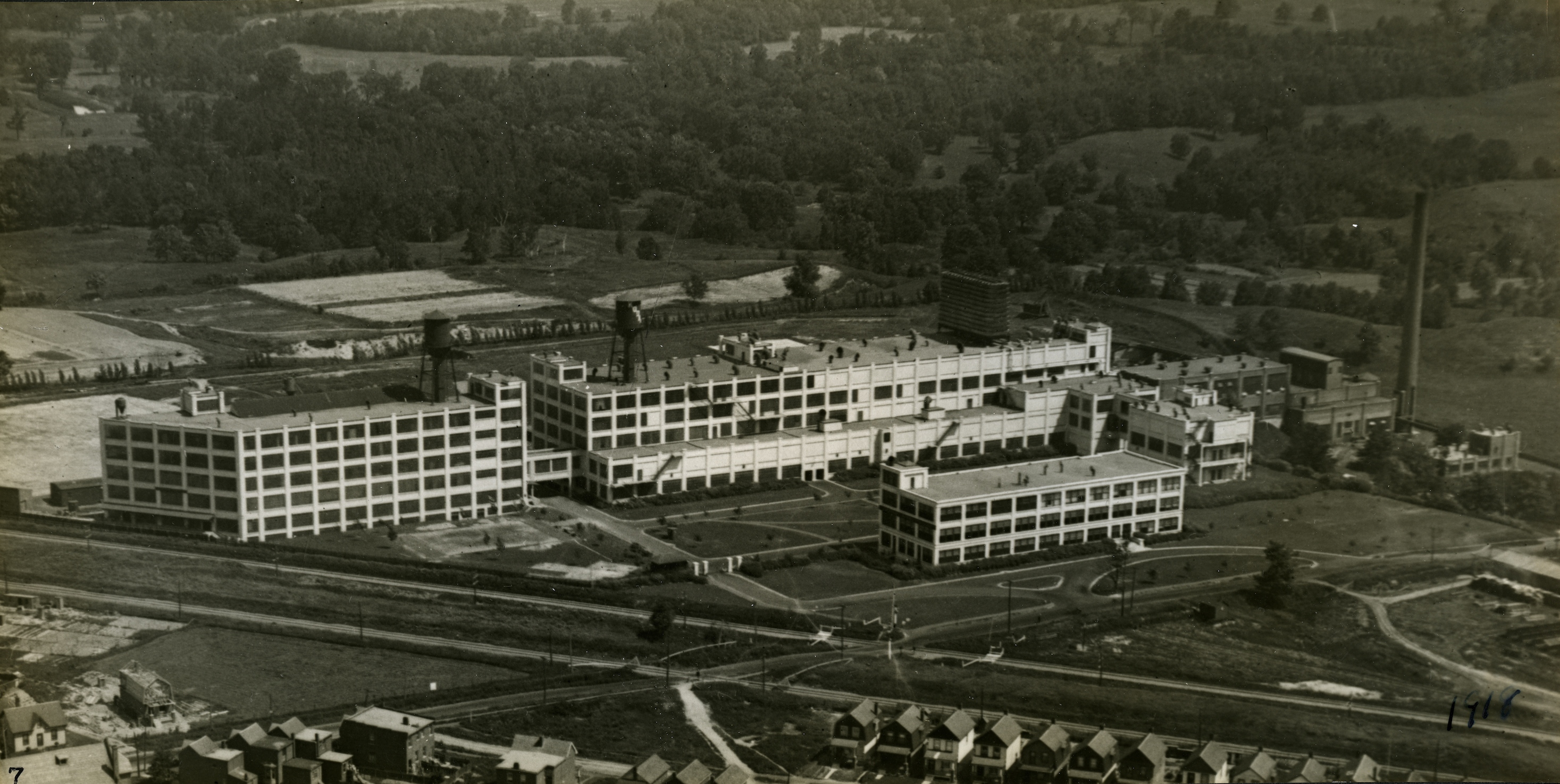

From link.Kodak Heights Aerial Photograph, 1918 (Note Eglinton Avenue West as a level crossing across the railway tracks.

Kodak Heights Pond, 1916

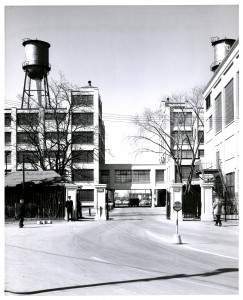

Kodak Heights Gateway, ca. 1960

Cafeteria, Building 9, Kodak Heights, 1948

Ladies Lounge, Building 9, Kodak Heights, 1964

Employees’ Building (Building 9), Kodak Heights, 2014

W. K. Lis

Superstar

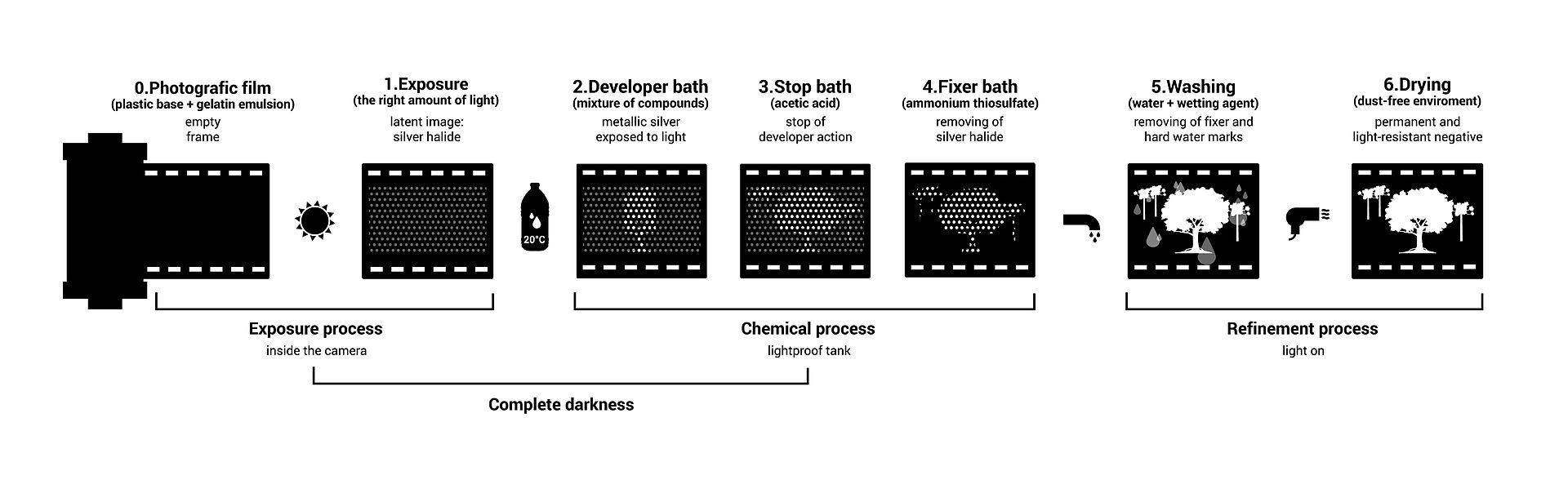

Only on a cloudy moonless night with all the lights (including street lights) out.…or possibly the stop bath.

42

From link.

drum118

Superstar

June 16

Starting to near completion with road and sidewalk being rebuilt for the westbound curb lane and new lane at Weston Rd. Rest of the month will be a bitch to travel on Eglinton from full closure with single lane changing direction depending on the day and week

Lot more up on site including GO/UPX Platforms

Starting to near completion with road and sidewalk being rebuilt for the westbound curb lane and new lane at Weston Rd. Rest of the month will be a bitch to travel on Eglinton from full closure with single lane changing direction depending on the day and week

Lot more up on site including GO/UPX Platforms

ProjectEnd

Superstar

To any of the more transit-focused folk here: did Metrolinx ever release any costing for this facility? RealNet doesn't even have a land transaction for it. Last recorded was in 2006 from Kodak to Metrus for $19.5m.

SaugeenJunction

Senior Member

Mount Dennis Station is coming along well. Some quick shots from today. As you can see, two Kitchener Line tracks have shifted into the station, with the third yet to be moved.

drum118

Superstar

Oct 21

There other photos in the Crosstown Thread. This is a station where photos can go into 4 different thread easy, yet they are the same photo.

There other photos in the Crosstown Thread. This is a station where photos can go into 4 different thread easy, yet they are the same photo.

W. K. Lis

Superstar

Meanwhile, in Potsdam, Germany...

A consortium of German companies including Siemens and Potsdam Transport Authority (ViP) has launched a three-year research project called Autonomous Tram in Depot (Astrid) to develop a fully automated tram depot.

From link.

The Astrid project is aimed at developing a fully automated tram depot.

Note the use of grass (oh the horrors) even in the depot. Something frowned upon by Toronto.

Autonomous tram depot research project launched in Potsdam

A consortium of German companies including Siemens and Potsdam Transport Authority (ViP) has launched a three-year research project called Autonomous Tram in Depot (Astrid) to develop a fully automated tram depot.

From link.

The other members of the consortium are Karlsruhe Institute of Technology (KIT), Germany’s Institute for Climate Protection, Energy and Mobility (IKEM), Codewerk, and Mapillary. The project is being funded by Germany’s Federal Ministry for Transport and Digital Infrastructure (BMVI) as part of its Modernity Fund research initiative.

The project will be carried out at ViP’s tram depot in Potsdam with the objective of developing a digital depot based on the operation of autonomous trams. Autonomous trials with a converted Siemens Combino LRV owned by ViP started last year on a 6km section of the Potsdam network and were extended to 13km earlier this year.

“The project’s technical feasibility will be demonstrated with autonomous service operation in the depot, such as running trams through a washing bay onto a siding,” Siemens explains.

Siemens says depot automation will be made commercially viable over the medium term as the first stage of autonomous tram operation. Astrid will consider the legal conditions necessary for the approval and operation of autonomous trams and the economic case for autonomous operation.

Siemens will develop the autonomous tram in the depot, and the tram’s integration into the data and system landscape via a data hub provided by Codewerk and localised and tracked using a Mapillary digital map. Codewerk will develop cloud and edge components for integrating the data of all systems and Mapillary will provide a cloud-based online platform for the collection and provision of street images. The data will be analysed with Artificial Intelligence and processed to provide digital maps.

ViP will provide the tram and depot infrastructure as well as access to data, systems and facilities, and evaluate the results as the depot operator. KIT will assist in the specification and digitalisation of the depot, automation of processes, and identification of necessary data, while IKEM will analyse and assess the legal and economic issues.

Milestone

“Astrid is the next big milestone on the way to autonomous trams” says Ms Sabrina Soussan, CEO of Siemens Mobility. “By automating time-consuming shunting operations in the depot, we want to better support our customers in ensuring sustainable value creation over the entire lifecycle as well as guaranteeing availability.”

“The fact that the driver is absent as a reference point for behavioural requirements, responsibility and liability presents major legal challenges and, specifically, challenges to operation approval,” says Mr Matthias Hartwig, mobility team leader with IKEM. “For commercial use scenarios, calculating costs and planning deployment, on the other hand, you can’t simply assume that only the driver is eliminated as a cost position. Other functions in the system will have greater importance, and the new technology must also be considered as a factor in operations and costs. There will in fact be a completely new operator model for the depot, and the project will develop this model and, as far as possible, support it with cost estimates.”

“We will be checking to see whether and how time-consuming shunting operations in a depot can be fully automated” says Mr Monty Balisch, managing director of ViP. “This is an interesting option for our present depot as well as for a possible further base of operations located in the north of Potsdam.”

The Astrid project is aimed at developing a fully automated tram depot.

Note the use of grass (oh the horrors) even in the depot. Something frowned upon by Toronto.

Transportfan

Senior Member

Meanwhile, in Potsdam, Germany...

Autonomous tram depot research project launched in Potsdam

A consortium of German companies including Siemens and Potsdam Transport Authority (ViP) has launched a three-year research project called Autonomous Tram in Depot (Astrid) to develop a fully automated tram depot.

From link.

The Astrid project is aimed at developing a fully automated tram depot.

Note the use of grass (oh the horrors) even in the depot. Something frowned upon by Toronto.

One city doing something innovative hardly warrants shaming Toronto for not doing it too.

W. K. Lis

Superstar

Unfortunately, that's what happened in the 1950's, when Toronto was "shamed" into building the Gardiner Expressway and Don Valley Parkway. It also was "shamed" into public transit cuts by Premier Mike Harris (1990's) and later Mayor Rob Ford (2010's) to "save money".One city doing something innovative hardly warrants shaming Toronto for not doing it too.